16t Single beam box girder electric goliath crane for steel factory

►Detailed Introduction

♦ The gantry crane is made up of six major parts: the bridge girder, ground beam, crane traveling mechanism,trolley, leg and electrical system.

♦ Bridge with box welded structure, with each driver traveling mechanism. All agencies are in the control room manipulation.

♦ Crane onductive form is divided into two kinds of cables and trolley line, a choice of ordering.

♦ A gantry crane has a similar mechanism supported by uprights, usually with wheels at the foot of the uprights allowing the whole crane to traverse.

►Advantages

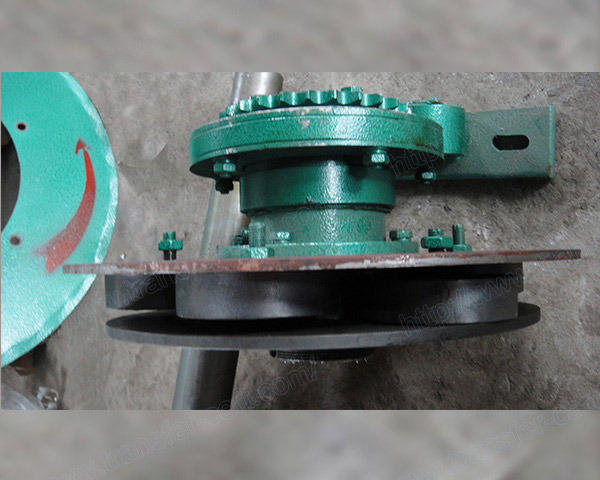

• This gantry crane has hard surface gear reducer and steel rope and three-in-one transmission mechanism.

• Double Girder Gantry Cranes can be outfitted with either crane hooks or grapples.

► Protective Device

The electric devices adjust speed without contactor spark module and fulfill frequency converter function to reach

mini-speed and double speeds, which makes traveling and lifting very steady.

| LiftingCapacity | t | 10 | 16 | 20/10.0 | 30/10.0 | 36/16 | 50/10.0 | ||

| Span | m | 18-35 | 2226 | 2630 | 32 | ||||

| WorkingSystem | Medium | Medium | Medium | Medium | Heavy | Heavy/Medium | |||

| LiftingHeight | Main | m | 11.5 | 10.512 | 10.5 | 10.5 | 11.5 | 12 | |

| Aux | 11 | 12 | 12 | 13 | |||||

| Speed | Hoist | Main | m/min | 18.4 | 12.3 | 9.2 | 10.4 | 10.4 | 6 |

| Aux | 18.4 | 18.4 | 12.3 | 18 | |||||

| TrolleyTravelling | 43.8 | 44.5 | 44 | 44 | 53 | 38.13 | |||

| CraneTravelling | 54.651.248.4 | 51.249.1 | 51 | 51.2 | 51.1 | 43.8 | |||

| TotalWeight | t | 63.2--135 | 75.5-105.5 | 79-132 | 125.4130 | 142148 | 204 | ||

| Max.WheelPressure | t | 23-40 | 36.4-23 | 30-42 | 3536 | 3839 | 48 | ||

| RailRecommended | P43 | P50 | P50QU70 | P50 | P50 | P50 | |||

| PowerSource | 380V50Hz3phase | ||||||||

►Usage

This series gantry crane is suitable for outdoor working conditions,such us shipyards,plant,warehouse,water station,power station and so on.

►Conventional Configurations

• Cabin and/or remote control;

• Wound rotor motor is used in each mechanism. Speed is changed by resistance;

• Working ambient temperature is -20°C-45°C. This is not suitable for lifting blazing & toxicants as well as explosion-proof or insulating working conditions.